Call Us

+1(956)26-99999

- Home

-

Air Compressors

+

- Oil Free Air Compressor

- KE Series Laser-specific Integrated Gas Station

- KQ series Permanent magnetpower frequency screw air compressor series +

- KN Series Laser Cutting Integrated Air Compressor +

- KC Series Portable Compact Air Compressor

- KG series Kapa Screw air compressor

- Centrifugal Air Compressor

- Double-stage compression permanent magnet variable frequency screw compressor KBseries

- Oil-free Screw Blower

- KM Series Diesel Driven Portable Screw Air-compressor

- Pressure Piston Compressor +

- KBO Series Oil-free screw air compressor series

- CAS Variable Frequency Screw Air Compressor

- KAAV SERIES Variable Frequency Screw Vacuum Pump

- Post treatment equipment series +

- About Kapa

- Custom Solutions +

- Blog +

- Contact Us

30HP 16Bar 4-in-1 integrated air compressor for laser catter

Ultimate Stability: Intelligent VFD control ensures constant air pressure, guaranteeing uniform, smooth cut surfaces free of stair-step patterns.

Exceptional Air Purity: Three-stage precision filtration (C/T/A) or high-efficiency oil-free solutions deliver outlet air purity meeting ISO 8573-1 Class 0 (0), protecting delicate laser lenses.

High Efficiency & Energy Saving: Permanent magnet synchronous motor and high-efficiency airend save 30%-40% energy compared to standard compressors, directly reducing your cost-per-part.

Smart Control: User-friendly touchscreen for real-time monitoring of pressure, dew point, and energy consumption, with fault pre-alarms for easier management.

Robust & Durable: Heavy-duty design for continuous operation in industrial environments. Easy maintenance ensures high uptime.

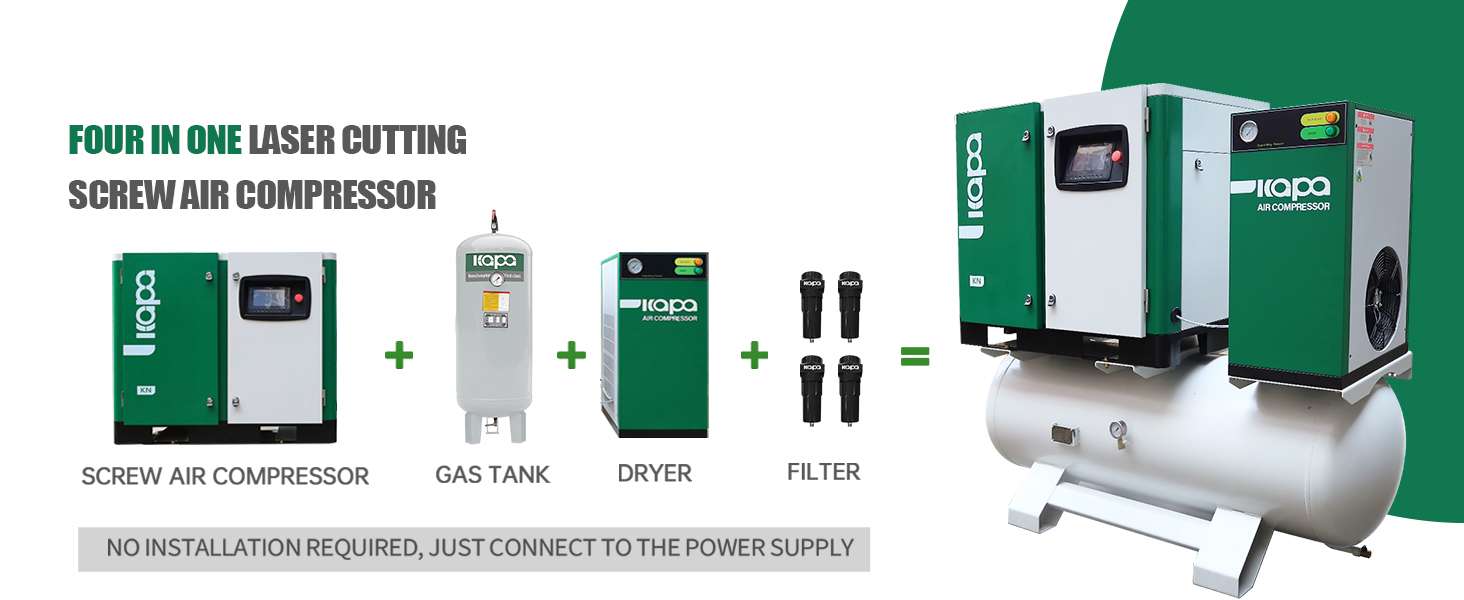

What is 4-in-1 integrated air compressor for laser cutting?

The 4-in-1 integrated air compressor for laser cutting is a versatile device designed to provide compressed air for various functions in laser cutting machines. It combines four essential components into a single unit, streamlining the setup and operation of laser cutting systems.

Air Compressor: The primary function of the device is to generate compressed air, which is crucial for several aspects of laser cutting, including assisting in material removal and keeping the cutting area clear of debris.

Air Dryer: Moisture in compressed air can adversely affect laser cutting quality and equipment performance. The integrated air compressor includes an air dryer to remove moisture, ensuring clean and dry air for optimal cutting results.

Air Filter: Dust and other contaminants present in the air can damage sensitive laser optics and components. The integrated air compressor features an air filter to trap particles, preventing them from entering the laser system and causing damage.

Air Tank: A built-in air tank provides a reservoir of compressed air, ensuring a consistent and reliable air supply to the laser cutting machine, even during peak operation. This helps maintain cutting quality and reduces the strain on the compressor motor.

Why Our Air Compressor is the Perfect Partner for Your Laser Cutter?

Ultimate Stability: Intelligent VFD control ensures constant air pressure, guaranteeing uniform, smooth cut surfaces free of stair-step patterns.

Exceptional Air Purity: Three-stage precision filtration (C/T/A) or high-efficiency oil-free solutions deliver outlet air purity meeting ISO 8573-1 Class 0 (0), protecting delicate laser lenses.

High Efficiency & Energy Saving: Permanent magnet synchronous motor and high-efficiency airend save 30%-40% energy compared to standard compressors, directly reducing your cost-per-part.

Smart Control: User-friendly touchscreen for real-time monitoring of pressure, dew point, and energy consumption, with fault pre-alarms for easier management.

Robust & Durable: Heavy-duty design for continuous operation in industrial environments. Easy maintenance ensures high uptime.

Compressed air constitutes a significant portion of your laser cutting operating costs. Our energy-saving screw air compressors, specifically designed for laser cutting, utilize permanent magnet variable frequency drive (VFD) technology to supply air on-demand, saving over 30% in energy compared to fixed-speed models. With powerful air delivery and oil content as low as 0.1ppm, you achieve faster cutting speeds, smoother cut surfaces, and a drastically lower total cost of ownership. It's an investment that pays off long-term.

Details

01- One screen dual control

Real-time air quality monitoring; Internal and external double pressure display, cold coal gas pressure

02- Clean

Modular dryer, efficient water removal; Four level precision filter, close to oil free

03- Strong

Brand host, specially selected low speed, micro-vibration; Heavy-duty bearing ensures high gas volume and high stability

04- Quiet

Measured full-load running noise 65 dB; Can adapt to any silence requirements of the environment

Technical Parmeters

| KN Laser Industry Series/16BAR | |||||||||||||||

| Model | Nominal Power | Working Pressure | Free Air Delivery | Weight(KG) | Noise Level | Dimensions (LxWxH) | Outlet size | Packaging size | |||||||

| 60Hz | KW | HP | bar | psi | m3/min | cfm | KG | db(A) | (mm) | L*W*H(mm) | |||||

| KN11-16 | 11 | 15 | 16 | 232 | 1.01 | 35.67 | 540 | 70 | 1890 | 800 | 1710 | RP3/4 | 1930 | 840 | 1720 |

| KN15-16 | 15 | 20 | 16 | 232 | 1.54 | 54.38 | 570 | 70 | 1890 | 800 | 1710 | RP3/4 | 1930 | 840 | 1720 |

| KN18.5-16 | 18.5 | 25 | 16 | 232 | 1.87 | 66.04 | 620 | 70 | 2230 | 990 | 1860 | RP3/4 | 2270 | 1030 | 1870 |

| KN22-16 | 22 | 30 | 16 | 232 | 2.79 | 98.53 | 650 | 70 | 2230 | 990 | 1860 | RP1 | 2270 | 1030 | 1870 |

| KN30-16 | 30 | 40 | 16 | 232 | 3.28 | 115.83 | 670 | 72 | 2230 | 990 | 1860 | RP1 | 2270 | 1030 | 1870 |

| KN37-16 | 37 | 50 | 16 | 232 | 3.97 | 140.20 | 750 | 72 | 2350 | 1150 | 1920 | RP1 | 2390 | 1190 | 1930 |

Advantages of Kapa Brand

Innovate technology to protect the environment.Kapa listens, understands and meets the needs of customers.Save the environment, ensure to provide better services and solutions, save costs for users, and seek the largest growth space. The main purpose is to protect and save energy, stimulate the growth of economic productivity, comply with market demand, save energy and reduce environmental pollution. With the mission of "innovation embodies value", Kapa Company will continue to promote technological innovation and progress, achieve win-win with global partners, suppliers and employees, create a new world of "energy saving, environmental protection, intelligence and service" in the aerodynamic field, and strive to be a world-class enterprise with world-class standards.

Advantages

1. High quality control(CE, SGS, ISO14001/Energy saving certificate)

2. Fast Delivery( 25-30 days for large orders)

3. Good service for pre-sale, after-sale( strong technical support and professional after-sales team)

4. Small order acceptable( Ordering quantity according to your actual needs)

Contact Us

Upgrade Your Air Supply Now and Experience High-Quality Laser Cutting!

Contact us today for a customized solution and a free selection consultation.

| KN Laser Industry Series/16BAR | |||||||||||||||

| Model | Nominal Power | Working Pressure | Free Air Delivery | Weight(KG) | Noise Level | Dimensions (LxWxH) | Outlet size | Packaging size | |||||||

| 60Hz | KW | HP | bar | psi | m3/min | cfm | KG | db(A) | (mm) | L*W*H(mm) | |||||

| KN11-16 | 11 | 15 | 16 | 232 | 1.01 | 35.67 | 540 | 70 | 1890 | 800 | 1710 | RP3/4 | 1930 | 840 | 1720 |

| KN15-16 | 15 | 20 | 16 | 232 | 1.54 | 54.38 | 570 | 70 | 1890 | 800 | 1710 | RP3/4 | 1930 | 840 | 1720 |

| KN18.5-16 | 18.5 | 25 | 16 | 232 | 1.87 | 66.04 | 620 | 70 | 2230 | 990 | 1860 | RP3/4 | 2270 | 1030 | 1870 |

| KN22-16 | 22 | 30 | 16 | 232 | 2.79 | 98.53 | 650 | 70 | 2230 | 990 | 1860 | RP1 | 2270 | 1030 | 1870 |

| KN30-16 | 30 | 40 | 16 | 232 | 3.28 | 115.83 | 670 | 72 | 2230 | 990 | 1860 | RP1 | 2270 | 1030 | 1870 |

| KN37-16 | 37 | 50 | 16 | 232 | 3.97 | 140.20 | 750 | 72 | 2350 | 1150 | 1920 | RP1 | 2390 | 1190 | 1930 |

AIR COMPRESSOR MAINTENANCE

01

The air compressor shouldbe placed in a place withclean air and good ventilation.

02

The air compressor should be placedhorizontally, with the belt side facingthe wall, and the maintenancespaceshould be reserved.

03

Before repairing and disassemblingthe air compressor, please tum offthe power supply and dischargethe air in the air seam.

04

When wiring, check whether thefan rotation direction is consistentwith the arrow direction.

ENERGY SAVING THCHNOLOGY

The starting power of the original system is 555kw,and the starting power of the new system is 320kw.

Power saving of 17000o kWh per month

The starting power of the original system is 240kW,and the starting power of the new system is 132kw.

Power saving of 54000 kWh per month

The starting power of the original system is 446kW,and the starting power of the new system is 325kW.

Power saving of 86000 kWh per month

The starting power of the original system is 690kw,and the starting power of the new system is 420kw.

Power saving of 260000 kWh per month

The starting power of the original system is 732kW,and the starting power of the new system is 50okw.

Power saving of 167000 kWh per month

The starting power of the original system is 430kw,and the starting power of the new system is 320kw.

Power saving of 79000 kWh per month

RELATED PRODUCTS

Inquiry